Printing is an essential aspect of communication and branding, transforming ideas into tangible, visually striking outputs. From businesses promoting their services to individuals cherishing memories through photo prints, printing has a significant impact on daily life. In this blog, we explore the various types of printing, the processes involved, and what to expect from each type in terms of results.

1. Offset Printing

What is Offset Printing?

Offset printing is a traditional method where the inked image is transferred (or “offset”) from a plate to a rubber blanket and then onto the printing surface. It is widely used for high-volume print jobs like newspapers, brochures, and magazines.

Offset Printing Process:

- Plate Creation: Each color requires a separate plate.

- Ink Application: Ink is applied to the plates.

- Offset Transfer: Inked plates transfer the image to a rubber blanket.

- Printing: The image is finally pressed onto the paper.

Expected Results:

- High Quality: Crisp images and consistent color tones.

- Cost-Effectiveness: Best for large quantities.

- Durability: The prints are long-lasting and resistant to fading.

2. Digital Printing

What is Digital Printing?

Digital printing directly transfers digital files to a variety of media, bypassing the need for plates. It is ideal for smaller print runs and personalized projects.

Digital Printing Process:

- File Preparation: The digital file is set up and adjusted for printing.

- Printing: The file is sent directly to the printer.

- Finishing: Options like lamination or binding can be added.

Expected Results:

- Speed: Quick turnaround time.

- Flexibility: Easy customization for each print.

- Cost: Economical for short runs but may be pricier per unit for large volumes.

3. Screen Printing

What is Screen Printing?

Screen printing involves creating a stencil (or “screen”) and using it to apply layers of ink onto the printing surface. It is commonly used for fabrics, ceramics, and promotional items like mugs.

Screen Printing Process:

- Stencil Preparation: A design is transferred onto a mesh screen.

- Ink Application: Ink is pressed through the stencil onto the surface.

- Curing: The print is heat-cured to ensure durability.

Expected Results:

- Vibrancy: Bright and durable colors.

- Texture: Ink creates a slightly raised texture.

- Versatility: Works on various materials.

4. Flexography Printing

What is Flexography?

Flexography uses flexible relief plates to print on various surfaces, including plastics, metals, and paper. It is commonly used for packaging and labels.

Flexography Printing Process:

- Plate Preparation: A flexible plate is created.

- Ink Application: Water-based or UV-curable ink is applied to the plate.

- Printing: The inked plate transfers the design to the substrate.

Expected Results:

- High Speed: Ideal for large-scale production.

- Consistency: Smooth and even print quality.

- Cost-Effective: Affordable for high-volume printing.

5. Gravure Printing

What is Gravure Printing?

Gravure printing uses engraved cylinders to transfer images. It is best suited for high-volume, high-quality prints such as magazines, wallpapers, and gift wraps.

Gravure Printing Process:

- Cylinder Engraving: Image areas are engraved onto a cylinder.

- Ink Application: Ink fills the engraved areas.

- Printing: The cylinder presses the ink onto the paper.

Expected Results:

- Detail: Exceptional image clarity and fine detail.

- Durability: Long-lasting prints.

- Volume: Economical for very high quantities.

6. Large Format Printing

What is Large Format Printing?

Large format printing produces oversized prints, such as banners, posters, and billboards, using specialized printers.

Large Format Printing Process:

- Design Preparation: The file is adjusted for the large format.

- Printing: High-resolution inkjets print the design.

- Finishing: Options like laminating or mounting enhance durability.

Expected Results:

- Visibility: Sharp and vibrant colors that capture attention.

- Durability: Designed to withstand environmental elements.

- Impact: Ideal for marketing and advertising.

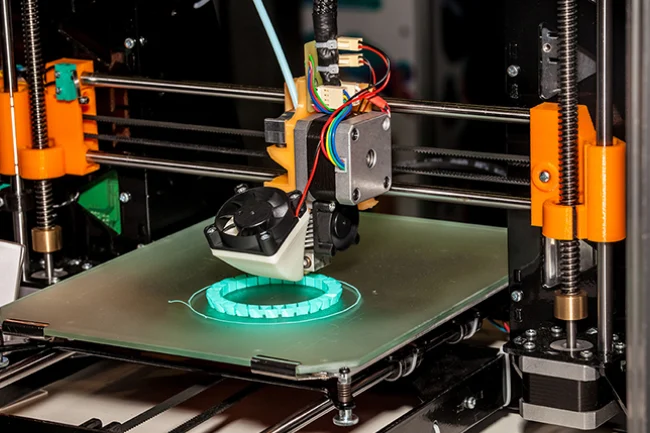

7. 3D Printing

What is 3D Printing?

3D printing creates three-dimensional objects by layering material based on a digital model. It is used in industries ranging from healthcare to automotive.

3D Printing Process:

- Modeling: A 3D model is designed using CAD software.

- Slicing: The model is divided into layers.

- Printing: Material is deposited layer by layer to build the object.

Expected Results:

- Precision: Intricate details and complex designs.

- Customization: Perfect for prototyping and bespoke products.

- Innovation: Endless possibilities for creative applications.

Why Choose Signfix for Your Printing Needs?

At Signfix Industrial Limited, we understand that every print project is unique, requiring precision, creativity, and reliability. With over 12 years of expertise in the printing industry, we are equipped to handle diverse printing needs—from small custom jobs to large-scale projects.

What Sets Us Apart?

- State-of-the-Art Technology: We utilize the latest equipment for superior print quality.

- Tailored Solutions: Our team collaborates with clients to deliver personalized results.

- Timely Delivery: We meet deadlines without compromising on quality.

- Exceptional Service: Our customer-centric approach ensures satisfaction at every step.

Whether you need eye-catching banners, durable labels, or vibrant brochures, Signfix Industrial Limited is your go-to printing partner in Nigeria. Our commitment to excellence ensures that your brand stands out and leaves a lasting impression.

Contact us today to bring your ideas to life with unparalleled printing services. Visit our website at signfix.ng or call us at +234 903 336 6660 or email support@signfix.ng and info@signfix.ng to get started. Let’s create something extraordinary together!